Goldleaf Manufacturing

The Gold Leaf manufacturing process has an over 5.000 years tradition and basically remained the same over this time. It is still for the most part handcraft, only a few production steps can be handled by machines.

Gold Leaf is a alloy of gold, silver and copper. Special alloys made from platinum or palladium. Depending on the addition of the individual alloying components, different carats can be achieved.

MANUFACTURING PROCESS

MELTING The alloying components are being melted at approxoximately 1.200 – 1.300°C and poured into gold bar. Various “colours” can be created according to the addition and quantity of the different metals.

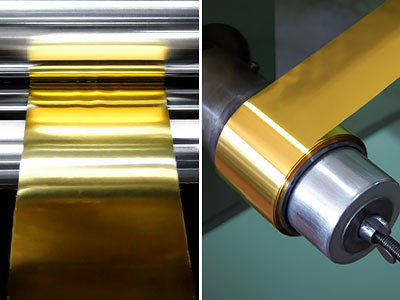

ROLLING The cooled down gold bar will mechanically rolled out into a thin gold ribbon (approx. length 100 metre, width 4 centimetre). Between the rolling processes, the gold ribbon has to be soft annealed consistently to avoid brittleness.

LOT The ready rolled gold ribbon is being cut into squares (size of 40 x 40 mm) and filled into special paper packets called “Lot” (greaseproof paper). Before this happens, the “Lot” has to be prepared with a special gypsum. This is necessary, so that the gold doesn’t stick on the paper during the beating process.

1. BEATING PROCESS The “Lot” is being put in a cross-band made of calf leather and beaten out with hammers to a size of about 160 x 160 mm.

QUALITY CONTROL After controlling of the first beating process, the beaten “Lot” with the gold is being cut into nine parts.

MOULD The gold leaf is being separated from the “Lot” and filled into the mould. Through the second beating process, the gold gets it’s final thickness of approximately 1/8000 mm – 1/10000 mm.

QUALITY CONTROL The gold leaf is being taken out of the mould by experts and checked carefully for possible flaws.

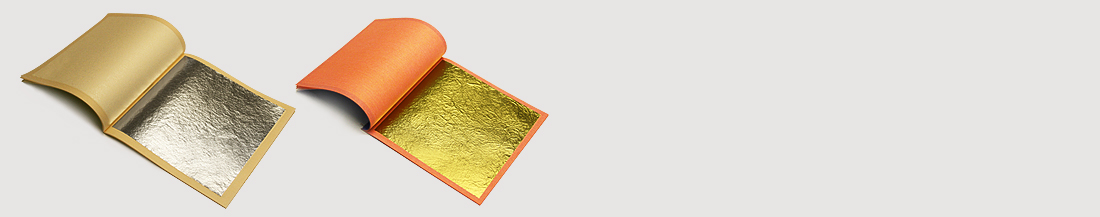

CUTTING / PACKAGING The gold leaf is being cut into the respective size (standard size 80 x 80 mm) and being carefully inserted into tissue paper booklets with 25 leaves each.